Radiant Industries is a prominent Manufacturer, Supplier and Exporter of Robotic Pre-Filled Syringe Filling and Closing Machine in South Africa.

Our Manufacturing unit is based in Ahmedabad, Gujarat, India.

What Is a Robotic PFS Filling and Closing Machine?

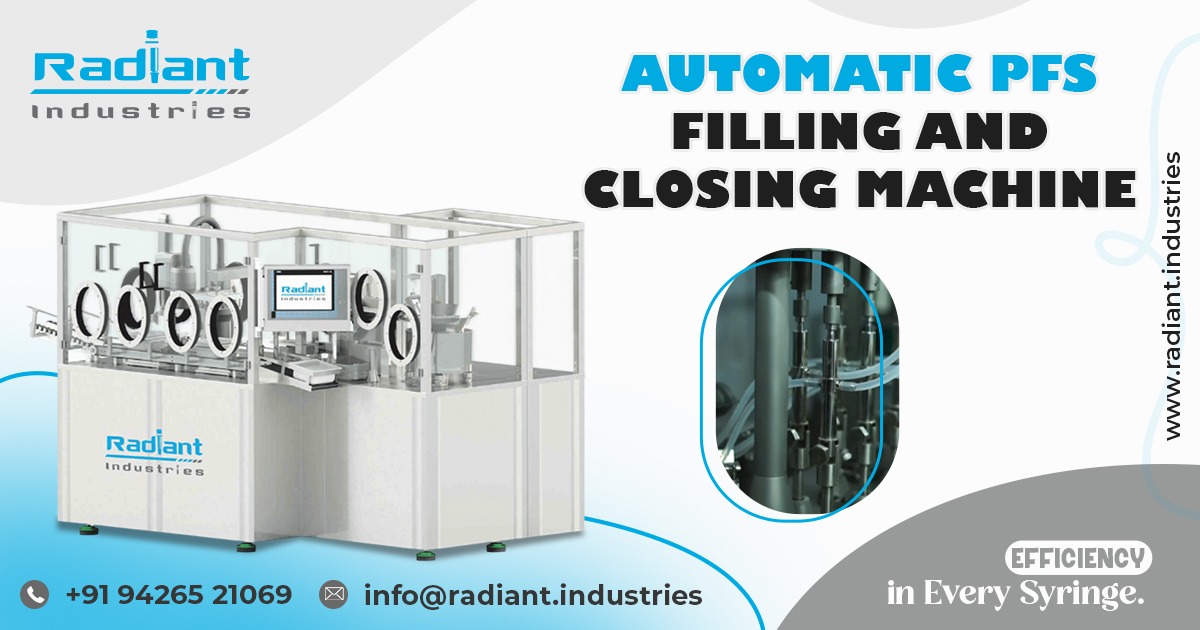

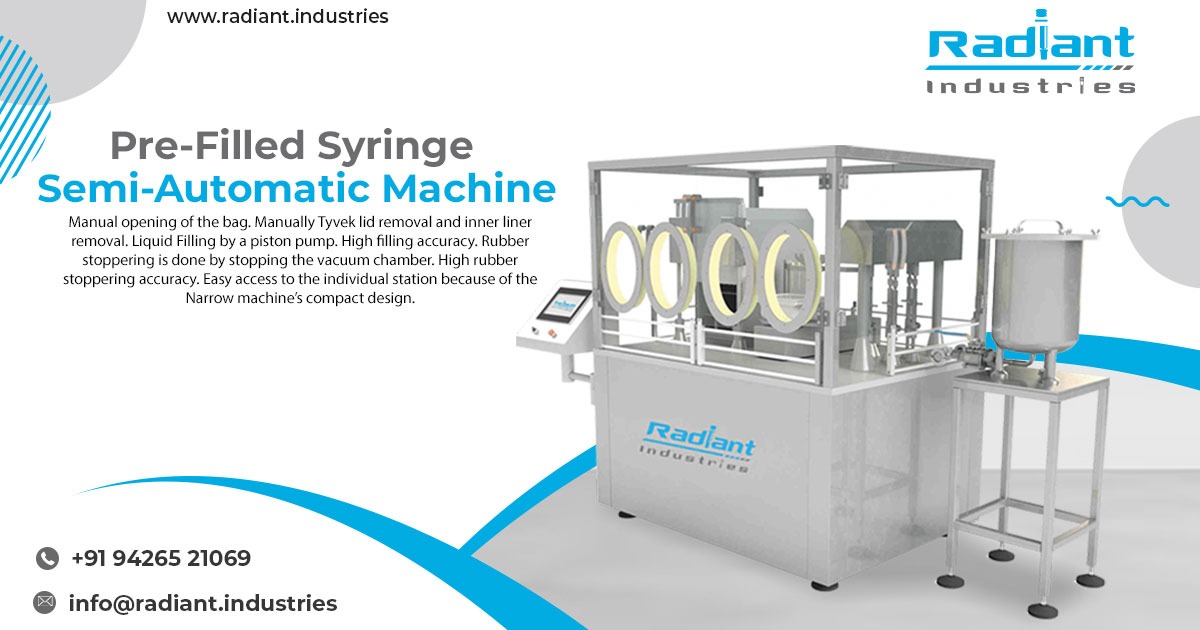

A Robotic PFS Filling and Closing Machine is an automated aseptic packaging system that:

• Precisely fills liquid drug formulations into pre-filled syringes.

• Performs accurate plunger insertion and closing.

• Ensures sterile handling through robotic manipulation.

• Maintains environmental control using laminar airflow and isolation zones.

Our Robotic PFS Filling and Closing Machine integrates robotics, laminar airflow control, and zone isolation to deliver a reliable, high-performance filling and sealing solution.

Designed for high accuracy, sterility, and automation efficiency, this system is engineered specifically for Pre-Filled Syringe (PFS) processing.

This Robotic PFS Filling and Closing Machine from Radiant Industries represents a next-generation solution for precision-driven, contamination-controlled pharmaceutical packaging.

Why Choose This System?

Pharmaceutical manufacturers choose robotic PFS solutions because they offer:

• Exceptional filling accuracy

• Reduced contamination risk

• Compliance with GMP and aseptic standards

• Minimal manual handling

• Consistent product quality

• Optimized production efficiency

This system is ideal for facilities seeking automation, sterility assurance, and regulatory confidence.

Key Features of Robotic PFS Filling and Closing Machine:

Waste Recovery System

Minimizes product loss and improves yield efficiency.

Automated Tub Transfer

Smooth, robotic syringe handling with minimal operator interaction.

Dual-Zone Isolation

Separation of critical aseptic processes for enhanced contamination control.

Controlled Laminar Flow

Uniform airflow ensures sterile working conditions.

Robotic Precision Handling

Accurate syringe positioning and manipulation.

Integrated Filling & Closing

Streamlined workflow from filling to plunger insertion.

Applications of Robotic PFS Filling and Closing Machine:

This machine is ideal for:

- Injectable drug manufacturing

- Vaccines and biologics

- Biotechnology products

- Ophthalmic formulations

- Hormonal and critical care drugs

- Sterile liquid pharmaceuticals

Frequently Asked Questions (FAQs):

How does robotic automation improve performance?

Robotics ensures consistent accuracy, reduced contamination risk, and faster processing.

Does the machine reduce product wastage?

Yes, the Waste Recovery System significantly minimizes losses.

Can the machine handle different syringe sizes?

Yes, depending on configuration and tooling customization.

Is the system GMP compliant?

Yes, it is designed to meet pharmaceutical GMP requirements.

Radiant Industries is a prominent Manufacturer, Supplier and Exporter of Robotic Pre-Filled Syringe Filling and Closing Machine in South Africa Including Johannesburg, Cape Town, Soweto, Gqeberha, Pietermaritzburg, Durban, Pretoria, Rustenburg, Newcastle, East London, Katlehong, Khayelitsha, Randburg, Roodepoort, Mitchells Plain, Boksburg, Bloemfontein, Germiston, Centurion, Kimberley, Sandton, Klerksdorp, Bethelsdorp, Kempton Park, Nqutu, Kroonstad, Benoni, George, Potchefstroom, Pinetown, Krugersdorp, Mthatha, Polokwane, Springs, Alberton, Upington, Winterveld, Parow, Paarl, Empangeni, Witbank, Uitenhage, KwaDukuza, Worcester, Grahamstown, Oudtshoorn, Ermelo, Stellenbosch, Sasolburg, Thaba Nchu, Kwamhlanga, Thohoyandou, Queenstown, Odendaalsrus, Bethal, Mossel Bay, Wellington, Queensburgh, Phuthaditjhaba, Kokstad, Edenvale, Vryheid, Kuilsrivier, Bothaville, Parys, Grabouw, Despatch, Vredenburg.

Call Us:

+91 94265 21069

Email Us:

info@radiant.industries

For further inquiries or customized solutions, feel free to contact us.