Radiant Industries is a prominent Manufacturer and Supplier of Pre-Filled Syringe Semi-Automatic Machine in Madhya Pradesh, India.

Our manufacturing unit is based in Ahmedabad, Gujarat, India.

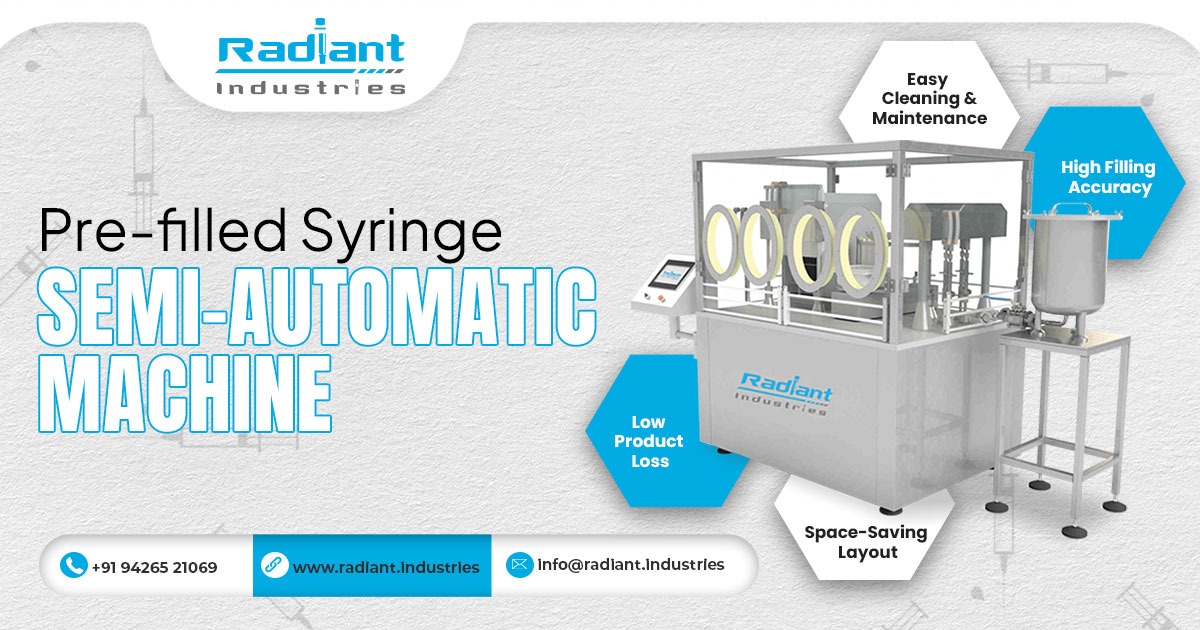

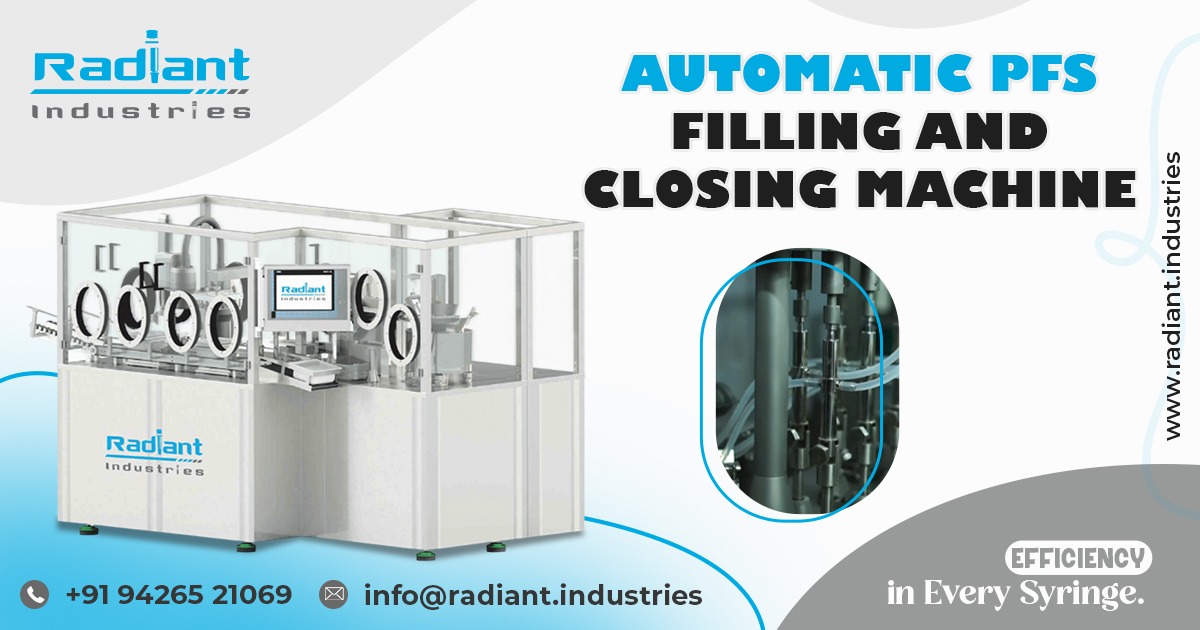

A Pre-Filled Syringe Semi-Automatic Machine accurately fills sterile syringes with liquid medicines securely during pharmaceutical production processes.

It performs controlled filling, plunger insertion, and stoppering while minimizing product loss and ensuring compliance with GMP and pharma regulatory standards.

This advanced machine supports the semi-automatic filling and stoppering of liquid medications into sterile syringes, ensuring contamination-free, high-precision dosing.

Radiant Industries offers a PFS semi-automatic machine ensuring superior accuracy, sterility, efficiency for pharmaceutical filling operations solutions.

Benefits of Pre-Filled Syringe Semi-Automatic Machine:

High Filling Precision – Equipped with advanced dosing pumps for accurate filling.

GMP & FDA Compliant Design – Ensures safe and sterile operations.

Flexible Design – Supports multiple syringe sizes and viscosities.

Compact & User-Friendly Interface – Semi-automatic controls allow easy operation.

Low Maintenance – Designed with smooth surfaces and easy-to-clean components.

High Productivity – Suitable for small to medium manufacturing batches.

Cost-Effective System – Provides automation benefits without high investment.

Reliable Dosing Accuracy – Reduces wastage and enhances product quality.

Hygienic Stainless Steel Construction – Ensures sterile and contamination-free operations.

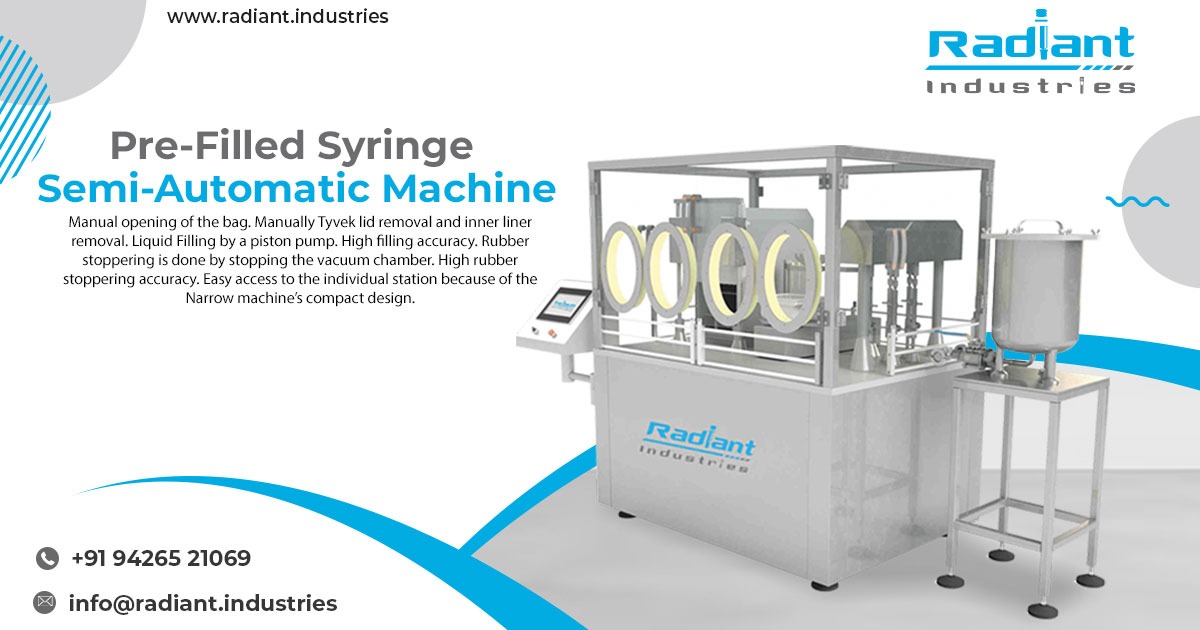

Process – How the Pre-Filled Syringe Semi-Automatic Machine Works

- Syringe Preparation:

Sterile syringes are manually loaded into the machine. - Precise Filling:

The dosing pump fills the liquid product into the syringe with accurate volume control. - Stopper Placement:

Stoppers are inserted manually or semi-automatically, depending on the model. - Air Removal & Sealing:

The syringe is inspected for air bubbles and sealed appropriately. - Ejection & Collection:

The machine discharges filled syringes into trays for inspection. - Quality Check:

Operators perform volume and sterility checks to ensure compliance.

Applications:

• Injectable medicines

• Vaccines and biological formulations

• Insulin and hormone-based injections

• Specialty injectables & critical care medications

• R&D laboratories and formulation development centers

• Small to medium-scale pharma production units

FAQs:

What is the production capacity of a semi-automatic PFS machine?

It typically fills 600–2,000 syringes per hour, depending on model and operator speed.

Can the machine handle viscous products?

Yes, servo piston pump models efficiently fill viscous and semi-viscous formulations.

What type of pump is used for dosing?

Customers can choose peristaltic, servo, or pneumatic pumps depending on their product type.

Radiant Industries offers Pre-Filled Syringe Semi-Automatic Machine in Madhya Pradesh, India including other locations like Agar, Malwa, Alirajpur, Anuppur, Ashoknagar, Balaghat, Barwan, Betul, Bhind, Bhopal, Burhanpur, Chhatarpur, Chhindwara, Damoh, Datia, Dewas, Dhar, Dindori, East Nimar, Guna, Gwalior, Harda, Hoshangabad, Indore, Jabalpur, Jhabua, Katni, Mandla, Mandsaur, Morena, Narsinghpur, Neemuch, Niwari, Panna, Raisen, Rajgarh, Ratlam, Rewa, Satna, Sehore, Seoni, Shahdol, Shajapur, Sheopur, Shivpuri, Sidhi, Singrauli, Ujjain, Umaria, Vidisha, West Nimar.

Contact Details:

Call Us: +91 94265 21069

Email: info@radiant.industries

For further inquiries or customized solutions, feel free to contact us.