Chemical dosing

Chemical dosing

BRIEF OVERVIEW - Chemical dosing

The dosing machine is an automated system for feeding the equipment with the products which contain liquid like lubricants and water

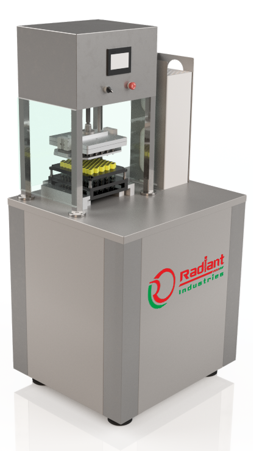

The dosing machine is used for automatic dosing of liquid reagents into blood collection tubes. Different dosing machines are available for different product needs. This machine is specially designed for the pharmaceutical industry.

A unique tube falling device avoids collision between tubes, preventing damage to the outer wall and tube labels.

Detection for tube dropping, clogging and reverse tube ensures safe, stable, and efficient machine operation.

The supporting auxiliary tube managing box automatically transfers the managed tubes into material barrel, reducing labor

Filling dosage is adjustable through the touch screen, and is easy to operate. A drying device is optional.

A high precision and high stability ceramic pump filling process is used. The precision is up to 1% and will not be affected by pressure, voltage, time, or other factors.

The nozzle can be inserted into the nozzle for spraying, and the lifting height can be set from HMI.

Spray Nozzles with extended tips have been used for coating of the inside of both evacuated and non-evacuated Vacutainer® blood collection tubes (VBCT & BCT), with anticoagulants (EDTA K2, EDTA K3, Lithium Heparin, Sodium Heparin) ,and Blood Clotting Accelerants (Silica, Thrombin, Venom).

Radiant Industries technology has its advantages over conventional air systems due to its low velocity, air-less spray that can easily be controlled to coat targeted areas within devices and well as enabling layering of coatings. Other advantages to spray technology for VBCT & BCT include:

- High transfer efficiency resulting in consistent quantities of deposited reagents and lower costs of manufacturing.

- Manufacturing process validation (GMP, ISO 13485, etc) is made easier with consistent reagent deposition.

- Perfect for solvent free processes, which are non-hazardous, lower cost, and environmentally friendly.

BCA spraying machine, with highly atomized nozzle achieves accurate dosing and high stability. Straight-through design. No dead end. Easy to clean and maintenance

5 dosing nozzles–CERAMIC Injection pump, filling tolerance≤±5%, based on 20µL). The spray effective is even and high performance in order to make the final blood complete contact with chemical and have good anti-coagulation performance.

The nozzle can be inserted into the nozzle for spraying, and the lifting height can be set from HMI.

| Capacity | 15,000-20,000 pcs/h |

| Filling head | 1 nozzle / 5 nozzle / 10 nozzel |

| Filling accuracy | Anti-coagulant: ≤5%; Procoagulant:≤6%; Large dose:≤5% |

| Applicable tube size | Diameter 13mm - 16 mm ( Height 75mm or 100mm) |

| Compressed air consumption | ≤ 100L / minute, 0.5mpa≤P≤0.8Mpa |

| Power supply | AC 380V 50Hz |

| Power | 0.7Kw |

| Overall size (L*W*H) | 1200*1200*2000 mm |

| Weight | 400kg |

Optional Accessories & Benefits

- In-process check Online Air Bubble Detection system

- Servo control controls Robotic System

- CERAMIC Injection pump & FMI Pump & Pinch Valve & Rotary Pump & Cleaning System CIP SIP System

- 1 nozzle / 5 nozzle / 10 nozzle

- 21 CFR part 11 compliance / SCADA system

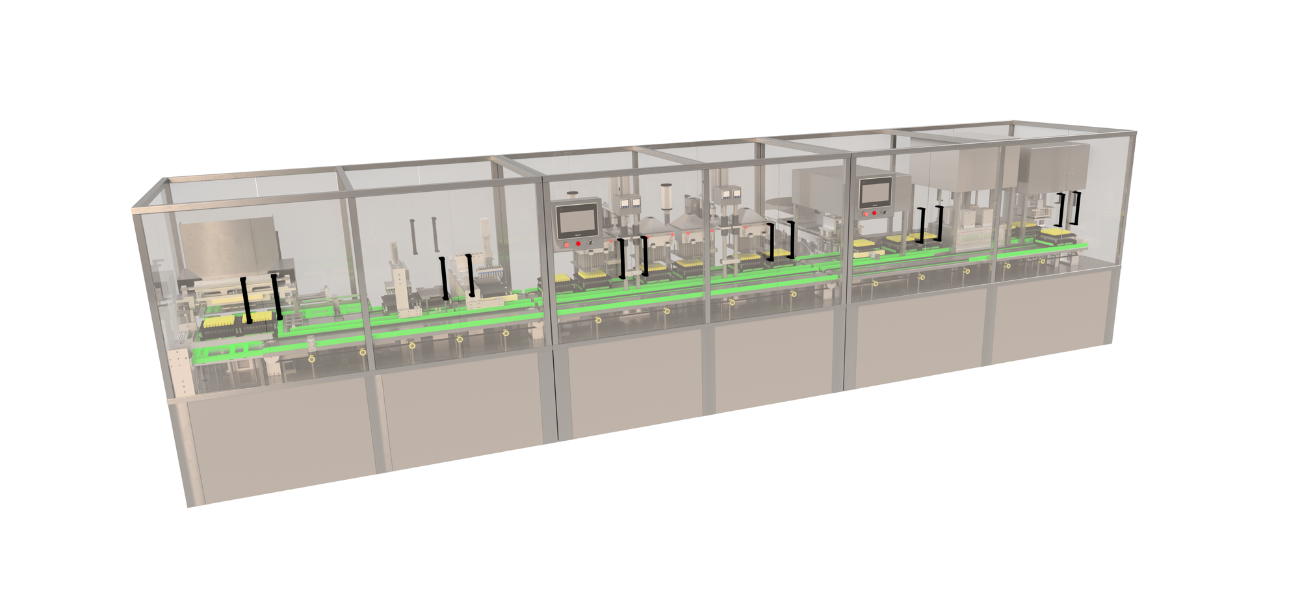

RADIANT INDUSTRIES FULLY AUTOMATIC

BLOOD COLLECTION TUBE ASSEMBLY LINE