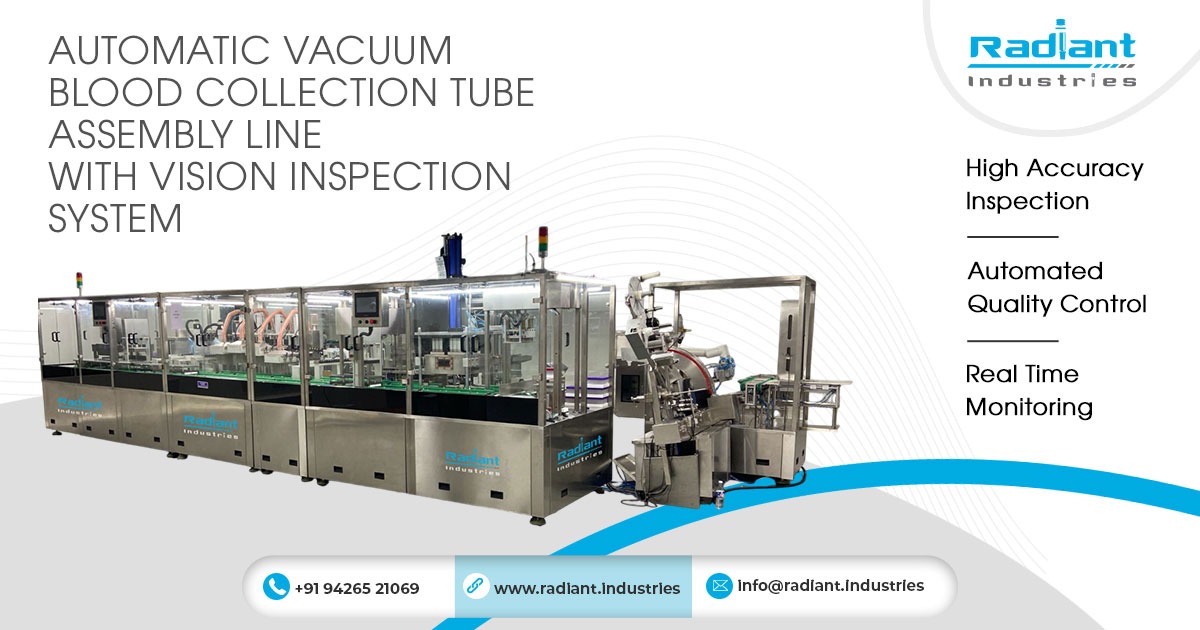

Radiant Industries is a trusted and reliable Manufacturer and Supplier of Automatic Vacuum Blood Collection Tube Assembly line in Uttar Pradesh.

Our registered office and manufacturing unit are located in Ahmedabad, Gujarat, India.

One of the most significant developments is the installation and operation of the Automatic Vacuum Blood Collection Tube Assembly Line.

This advanced production system automates and streamlines the entire process of manufacturing blood collection tubes, ensuring higher efficiency, hygiene, and consistency.

Introduction of Online Label Applicator Machine

The Online Label Applicator Machine plays a crucial role in the automated assembly line, applying labels directly onto the tubes during the assembly process without stopping or slowing down the production line.

This system ensures accurate label placement, reduces manual labor, minimizes errors, and increases overall productivity.

Advantages:

- Real-time labeling during tube movement

- High-speed label application (up to several hundred tubes per minute)

- Compatible with various tube sizes and label types

- Integration with barcode or QR code systems for traceability

Work of Automatic Vacuum Blood Collection Tube Assembly Line

The assembly line operates through a series of automated modules that perform specific tasks with precision and speed. Here’s an overview of its working process:

- Tube Feeding: Empty plastic or glass tubes are fed into the machine.

- Coagulation Agent/Solution Filling:The system accurately doses anticoagulants or clot activators.

- Cap Insertion & Sealing: The system applies and seals colored caps onto each tube.

- Vacuum Creation: The tube is vacuumized to the required negative pressure.

- Online Labeling: The label applicator places identification labels on the tubes.

- Inspection & Sorting: Tubes undergo quality checks before being sorted and packed.

Specification:

| Applicable Tube Size | Dia.: 13×75/100mm; Dia.: 16×100mm |

| Working Speed | 12000 – 18000 pcs/hour |

| Dosing Method and Accuracy | Anticoagulant: 5 dosing nozzles FMI metering pump, error tolerances ±5% based on 20μl Coagulant: 5 dosing nozzles precise ceramic injection pump, error tolerance ±6% based on 20μl Sodium Citrate: 5 dosing nozzles precise injection pump SS 316, error tolerance ±3% based on 100μL |

| Drying Method | PTC heating with high pressure fan. |

| Cap Specification | Downward type or upward type cap according to customer’s requirements. |

| Applicable Foam Tray | Interlaced type or rectangular type foam tray. |

| Power | 380-415 V / 50 HZ, 20 KW |

| Compressed Air | Clean Compressed Air Pressure: 0.8 – 1.0 Mpa |

| Space Occupation |

Features of the Assembly Line

- Fully Automated Operation: Reduces manual handling and human error.

- High Production Speed: Capable of assembling thousands of tubes per hour.

- Precision & Accuracy: Ensures consistent vacuum pressure and chemical dosing.

- Integrated Online Labeling: Real-time labeling system improves traceability and compliance.

- Modular Design: Allows customization and upgrades.

Radiant Industries is a Supplier of Automatic Vacuum Blood Collection Tube Assembly line in Uttar Pradesh and including locations in Kanpur, Lucknow, Ghaziabad, Agra, Meerut, Varanasi, Prayagraj, Bareilly, Aligarh, Moradabad, Saharanpur, Gorakhpur, Noida, Firozabad, Jhansi, Muzaffarnagar, Mathura-Vrindavan, Ayodhya, Rampur, Shahjahanpur, Farrukhabad-Fatehgarh, Budaun, Maunath Bhanjan, Hapur, Etawah, Mirzapur-Vindhyachal, Bulandshahr, Sambhal, Amroha, Hardoi, Fatehpur, Raebareli, Orai, Sitapur, Bahraich, Modinagar, Unnao, Jaunpur, Lakhimpur, Hathras, Banda, Pilibhit, Barabanki, Khurja, Gonda, Mainpuri, Lalitpur, Etah, Deoria, Ghazipur, Sultanpur, Azamgarh, Bijnor, Sahaswan, Basti, Chandausi, Akbarpur, Ballia, Tanda, Greater Noida, Shikohabad, Shamli, Awagarh, Kasganj.

For detailed information and inquiries, please feel free to contact us.

View Product: Click here