Radiant Industries is a Manufacturer and Supplier of Automatic Vacuum BCT Assembly Line in Mumbai, Maharashtra, India.

Our registered office and manufacturing unit are located in Ahmedabad, Gujarat, India.

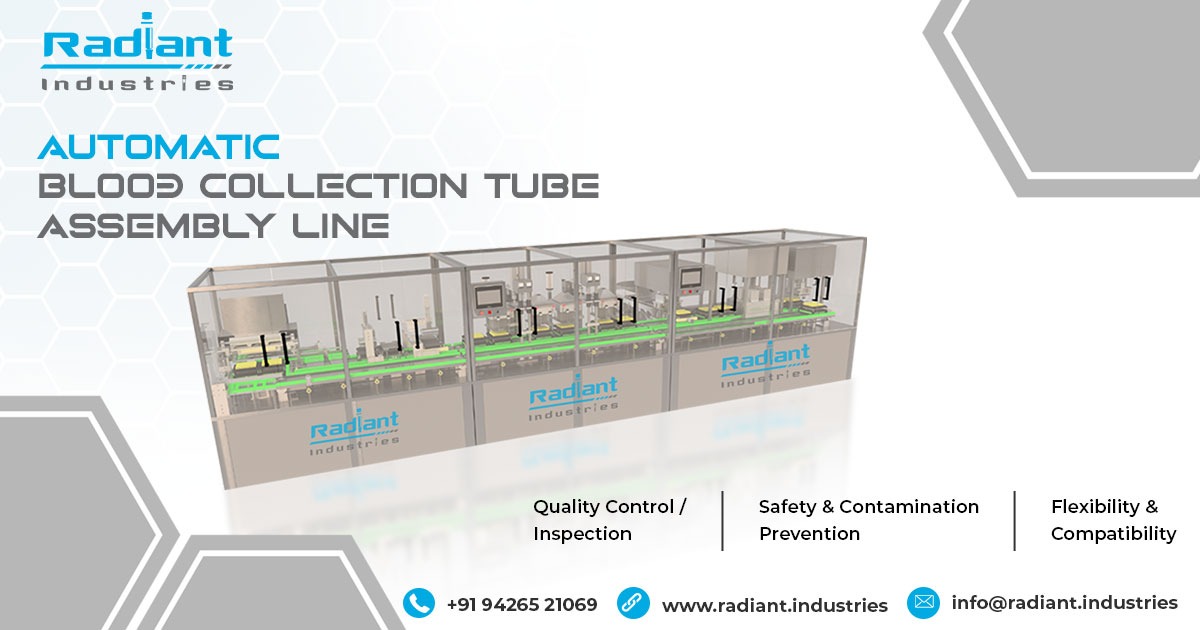

Radiant Industries proudly offers the Automatic Vacuum Blood Collection Tube Assembly Line for efficient, high-quality medical device manufacturing.

This advanced system integrates precise automation to deliver consistent, sterile vacuum tubes for global clinical diagnostic applications.

Ideal for medical manufacturers, it meets the growing demand for reliable, contamination-free blood collection solutions.

An Automatic Vacuum Blood Collection Tube Assembly Line produces essential tubes used for sterile blood sampling and secure storage.

These tubes preserve a vacuum environment to ensure accurate, hygienic blood collection for diagnostic use.

The fully automated system performs tube forming, stopper insertion, labeling, and packaging with minimal manual intervention.

This streamlined process enhances production speed, reduces labor costs, and ensures high product quality and consistency.

Features:

High Automation Level: Reduces human intervention and operational errors.

Integrated Quality Control: In-line sensors and vision systems to detect defects instantly.

Multi-Functional Modules: Handles tube molding, stopper insertion, vacuum sealing, labeling, and packaging.

User-Friendly Interface: Touchscreen control panels for easy operation and monitoring.

Flexible Production Capacity: Adjustable to handle different tube sizes and production volumes.

Compact Design: Space-saving footprint ideal for modern manufacturing floors.

Real-Time Data Monitoring: For performance tracking and predictive maintenance.

Applications:

Hospitals and Clinics

Medical Device Manufacturers

Diagnostic Laboratories

Pharmaceutical Industry

Research Institutions

FAQs:

Q1: What is the typical production capacity of the assembly line?

A1: Radiant Industries’ assembly lines can produce up to 20,000 tubes per hour depending on the configuration.

Q2: Can the assembly line handle different tube sizes?

A2: Yes, the line supports multiple tube sizes including 2ml, 3ml, 5ml, 7ml, and 10ml.

Q3: How does automation improve product quality?

A3: Automation reduces human error, ensures precise stopper placement, maintains vacuum integrity, and performs real-time defect detection.

Radiant Industries is an AAutomatic Vacuum BCT Assembly Line in Mumbai, Maharashtra, India including Mumbai, Pune, Nagpur, Thane, Pimpri-Chinchwad, Nashik, Satara, Solapur, Kalyan-Dombivli, Vasai-Virar, Aurangabad, Navi Mumbai, Solapur, Mira-Bhayandar, Bhiwandi-Nizampur, Jalgaon, Amravati, Nanded-Waghala, Kolhapur, Ulhasnagar, Sangli-Miraj-Kupwad, Malegaon, Akola, Latur, Dhule, Ahmednagar, Chandrapur, Parbhani, Ichalkaranji, Jalna, Ambarnath, Bhusawal, Panvel, Badlapur, Beed, Gondia, Satara, Barshi, Yavatmal, Achalpur, Osmanabad, Nandurbar, Wardha, Udgir, Hinganghat.

Feel free to contact us for more information and inquiries.