Tube Labeling & Online printing

Tube Labeling & Online printing

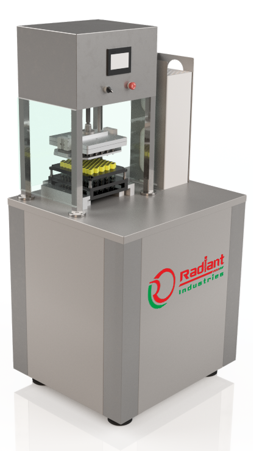

This machine is suitable for automatic labeling of the vacuum blood collection tube and other similar tube.

Good configuration, strong stability, high performance

Applicable for transparent label, high efficiency, no tube stucking.

Applicable for both transparent and opaque labels. Servo motor controls label sending, making it rapid and stable. Give up the traditional roller filling way, adopt the unique feed way to avoid tube stuck or breakage.

Adopt German Leuze GS photoelectric sensor, Panasonic / Delta servo motor, and the corresponding speed drive, which have made a good foundation for the rapid, high efficient and stable labeling.

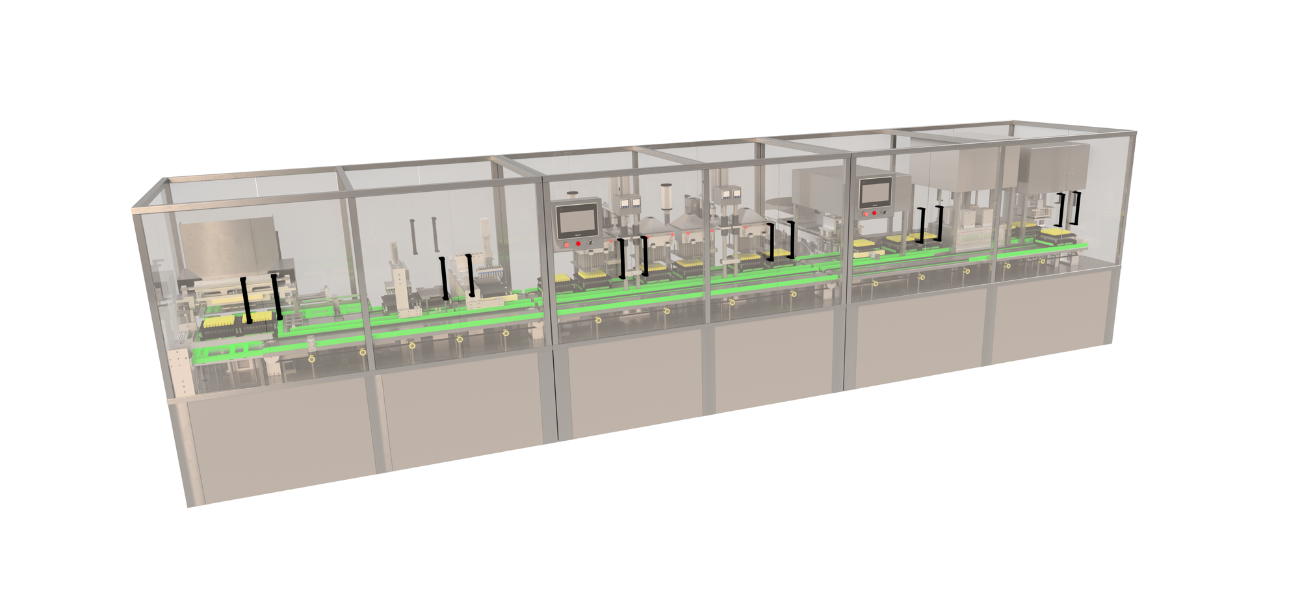

To ensure the effectiveness and efficiency of the production process, the machine is made up of a product transfer system, labelling and packaging equipment, a programmable logic control panel, an electronic panel, and other sophisticated functions. The blood tube labelling device’s entire moving component set of safety features has been considered.

A stepping motor is used to move the label, and photoelectric detection is used to inspect both the label and the tube. Maximum 15000 blood tubes can be labelled per hour on this sturdy labelling machine. Additionally, the label’s height can be altered to accommodate various label positions on the bottle. Depending on the needs of the application, we can offer safe and maintenance-free freight handling services.

-Speed: 200 to 300 as per tube size

-Leuze GS photoelectric sensor

-Servo motor for controlling label

-With Pie Hmi

-It can be with online printing system for batch code and date printing.

-Online connection with production line

-2nd step in the production line step is labelling.

-Using a labelling machine can efficiently apply stickers or labels on the products like containers, tubes

Technical Specification :

| Capacity | 12000-18000 pcs/h, (effected by label size and tube size) |

| Label | Both transparent and opaque label |

| Tube size | Dia.: ø13 - ø 16 mm, length: 75 mm - 100 mm |

| Labeling precision | ± 1 mm in length |

| Air consumption | no need air |

| Power Supply | 220V |

| Overall Size(LxBxH) | 2000 x 500 x 1700 mm |

| Weight | 200kg |

Optional Accessories & Benefits

- batch coding & label printing system Barcode

- Vision System , Servo controller & steper Controller

- HMI/PLC, 21 CFR part 11 compliance / SCADA system

RADIANT INDUSTRIES FULLY AUTOMATIC

BLOOD COLLECTION TUBE ASSEMBLY LINE