Radiant Industries:

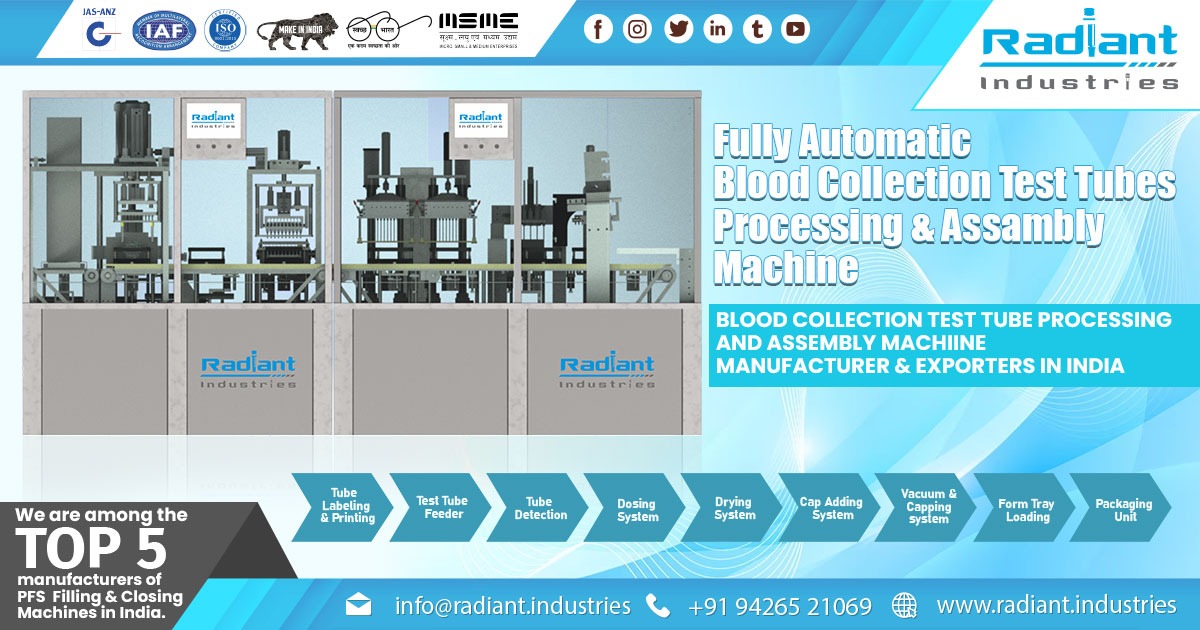

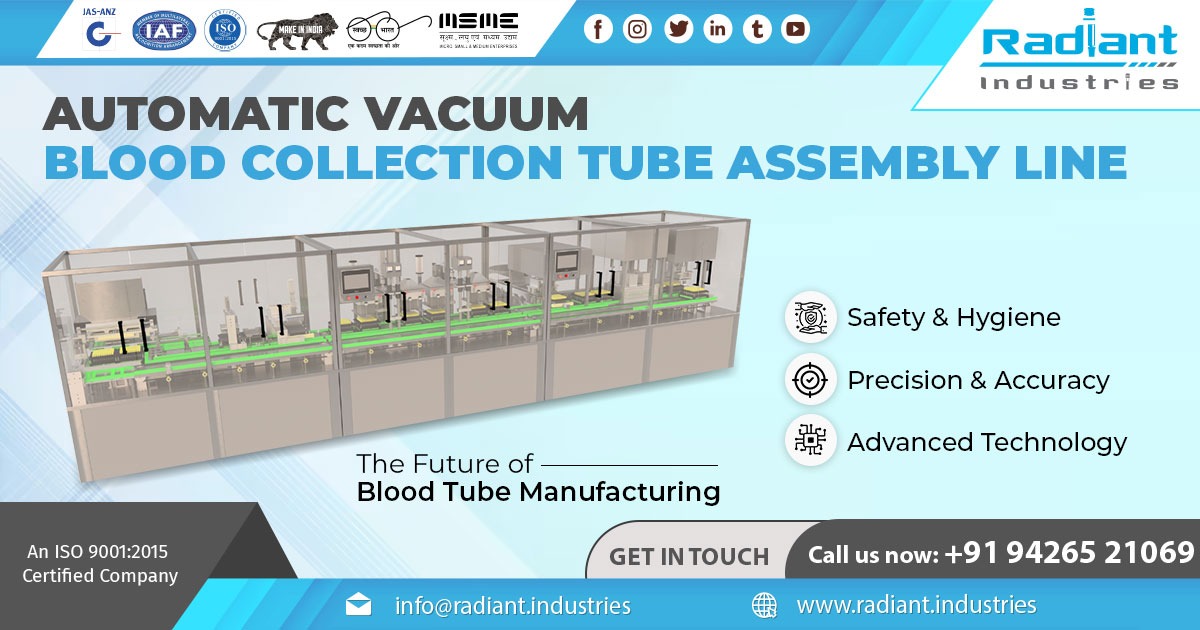

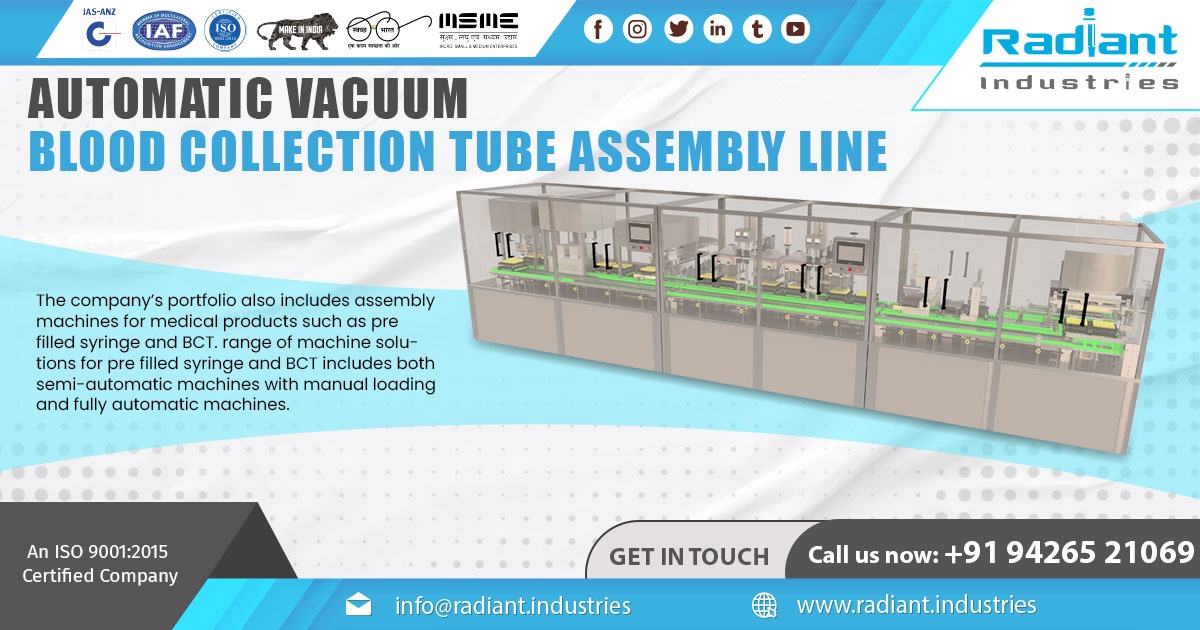

Radiant Industries introduces a state-of-the-art Fully Automatic Compact Blood Collection Tube Production Line, characterized by its compact design and adherence to current Good Manufacturing Practices (cGMP).

Elegantly designed, the machine operates fully automatically, encompassing key production stages within a compact footprint. It follows cGMP guidelines, ensuring product quality and compliance with industry standards.

The production line includes essential functions such as tube loading, chemical dosing, drying, cap adding, vacuum/non-vacuuming, cap pressing, form tray loading, and more.

Individual Programmable Logic Controller (PLC) and Human-Machine Interface (HMI) control ensure easy and safe operation. Highlighting the efficiency of the entire line is the fact that 3-4 workers can manage it.

Compared to other manufacturers, Radiant Industries’ equipment boasts unique features, including a smaller overall dimension, higher automation and stability, lower fault rates, and reduced maintenance costs.

Specifically designed for vacuum blood collection tubes, the production line showcases its specialized focus.These tubes typically feature a sterile glass or plastic design, utilizing a stopper to create a vacuum seal for precise volume depiction.

Vacuum blood collection tubes prevent needle stick damage by avoiding direct contact with needles, minimizing contamination risks.

The vacuum blood collection tube includes a double-pointed needle attached to a plastic tubular adapter, available in various gauge sizes.

Specifications:

Applicable Tube Size: Dia.: 13×75/100mm; Dia.: 16x100mm

Working Speed: 8000-10000 pcs/hour

Dosing Method and Accuracy: Various dosing methods, including FMI metering pump, ceramic pump, pinch valve, and rotary piston pump.

Drying Method: PTC heating with a high-pressure fan

Cap Specification: Downward or upward type caps based on customer requirements

Applicable Foam Tray: Interlaced or rectangular foam tray

Power: 380-415 V / 50 HZ/ 20 KW

Compressed Air: 6 to 8 bar

Space Occupation: 3510 (L) X 2600 (W) X 1800 (H) mm approx.

Service Coverage in Maharashtra:

Radiant Industries provides the Fully Automatic Compact Blood Collection Tube Production Line in Maharashtra, covering locations such as Mumbai, Pune, Nagpur, Nashik, Vasai-Virar, Solapur, Bhiwandi, Amravati, Kolhapur, Akola, Latur, Jalna, and more.